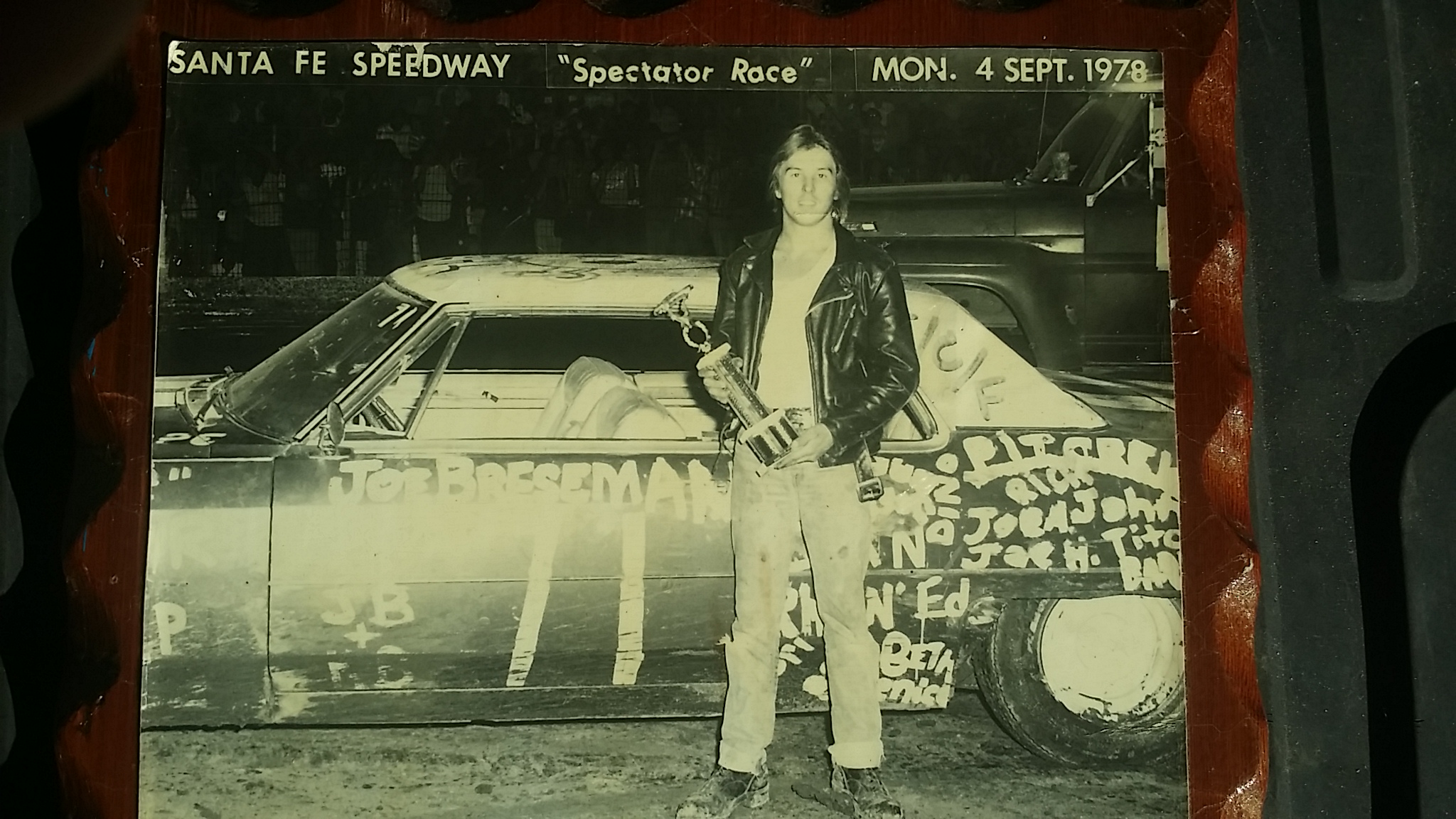

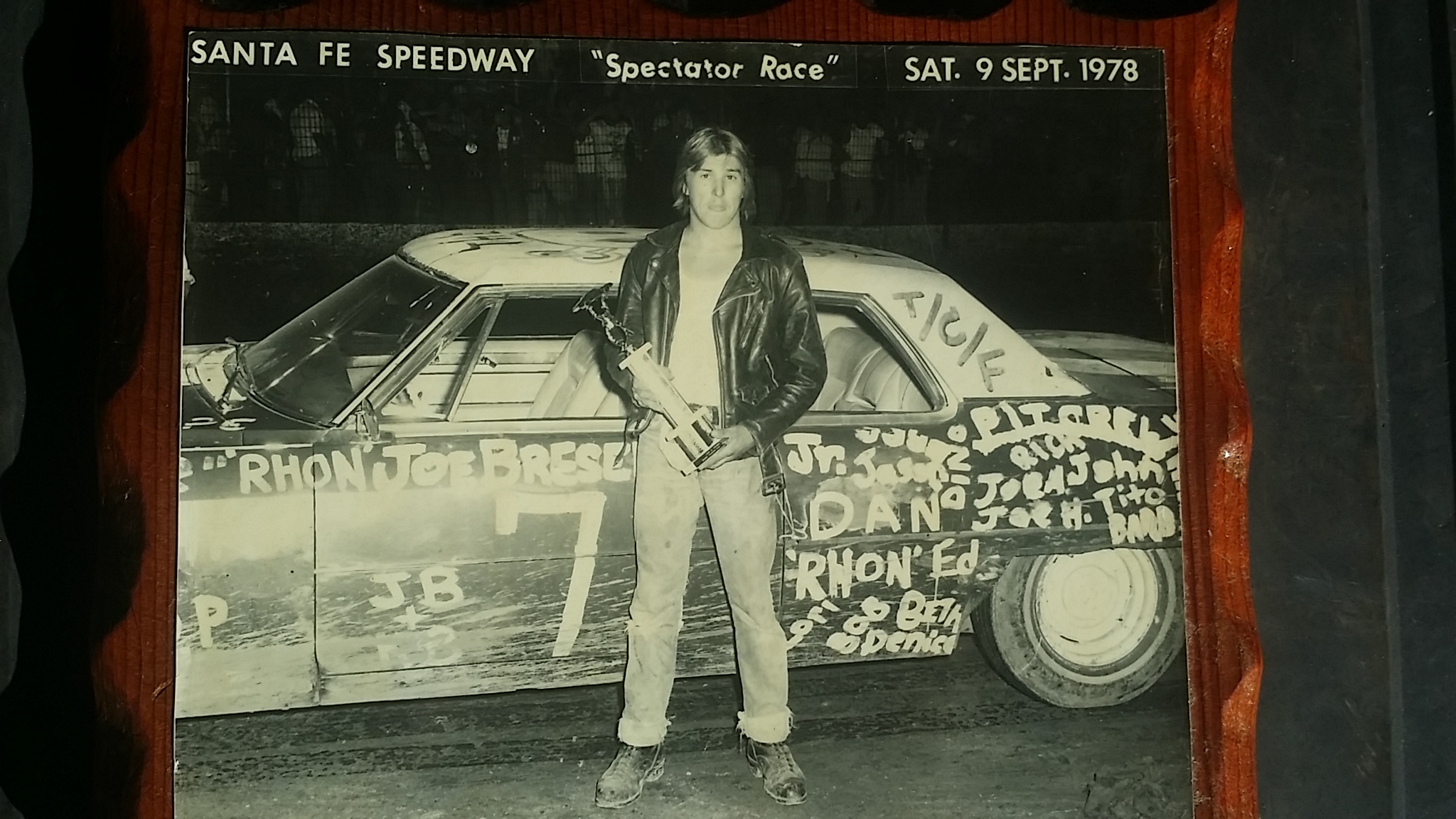

I started my mechanical ability by riding and working on my own mini bikes back when I was 9 years old, in 1969, with a new Honda 50 Mini Trail. I wanted to go faster, do wheelie's and race. At 11 years old I did it on a new Yamaha 60 Mini Enduro. In 1971, on my very first day of racing, I won all of my 5 Heats. I then advanced to a Yamaha 125. At age 13, I lived in Florida and had a Full Roll Bar Dune Buggy. The first weekend I had the Dune Buggy, I raced it all weekend and blew up the engine. I then learned how to work on cars and replaced three engines during the time I had it. At age 18, I started racing at Santa Fe Race Track in Illinois. I won my first two races in a row in two weekends, back in 1978 at age 18 with my high school car a 1965 Caddy with a 429 Cu. In. Engine.

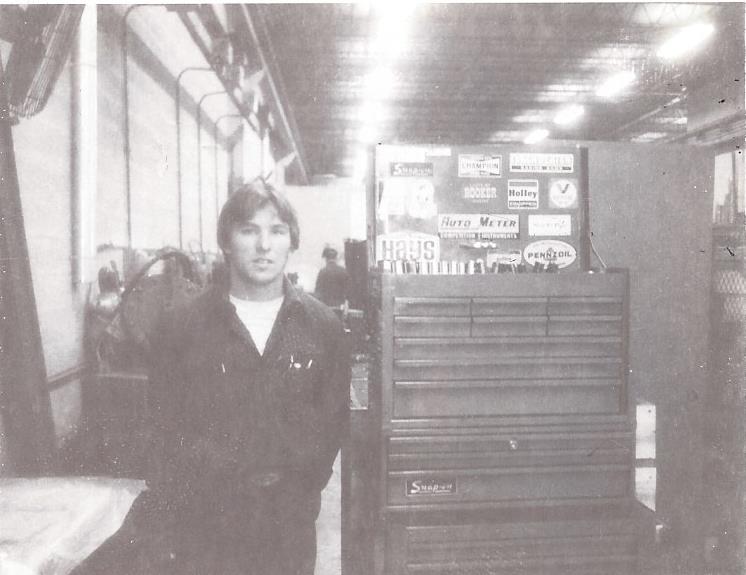

At Hernando High School in Florida I took every mechanical course offered then moved back to Illinois in 1977 and took Basic and Advanced Machine Shop. I then knew I wanted to be a Mechanic or Machinist or both as it ended to be after Triton College in 1981.

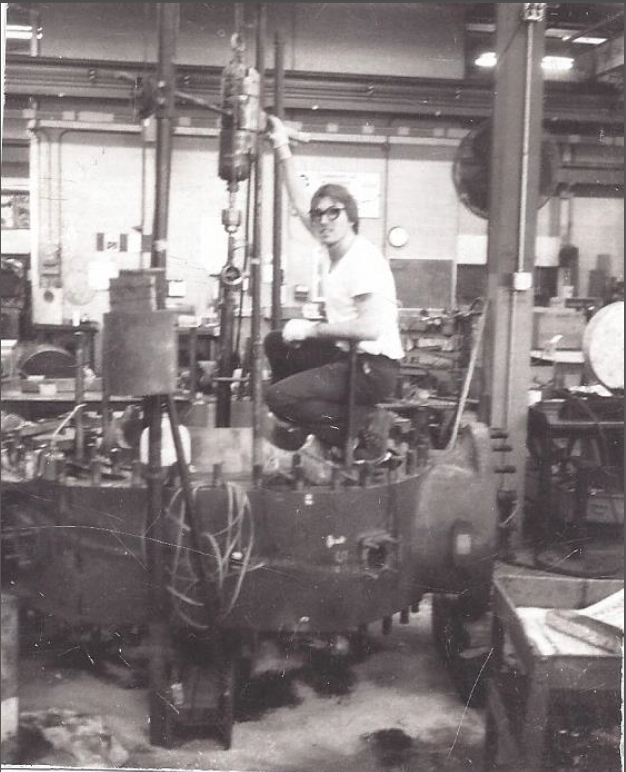

In 1981, after taking several Machine Shop Classes through National Tool and Die Institute of Washington DC, I was recruited through one of the members by a company named Commercial Machine Works. Commercial Machine Works was one of the largest companies in the United States that worked on all types and brands of Power House Equipment in operation manufactured across the United States and out of the country. At the time Commercial Machine Works was an Authorized Service Shop for Elliott YR Steam Turbines, Blowers and Centrifugal PAP Compressors. I loved working as a mechanic on all of these types of equipment.

From 1981 up until the start of B&G RESCO, in 2001, I used my Machinist and Mechanical skills as a Field Machinist and Field Mechanic and traveled all over the country for over 25 years, working on every manufactured turbine, pump, compressor, gearbox, blower and many other power house related equipment there was to work on, along the way for my previous employers. I am very thankful for my highly experienced coworkers and superiors who took me under their wing and taught me patiently.

My Mentors

My first mentor in this business was Francis Stirpe, whom began his career at Ingersoll Rand as a Serviceman, then worked his way up at Worthington from a serviceman to Vice President of Sales and Service. No one at the time could match his knowledge and skills in the reciprocating air and product compressor world. In 1983 Fran took me under his wing and was like a father to me teaching me as he was my mentor and I was his Protege. He said to me that I reminded him of himself when he was a young man. He worked with me patiently side by side in the field training me on rebuilding large Ingersoll Rand, Chicago Pneumatic, Gardner Denver, Pennsylvania, Frick ammonia and Worthington compressors. After one and a half years in the field Fran made me a Field Service Supervisor and gave me my first box of business cards with my name on them while I was on a three month job in Jamaica rebuilding a 1250hp IR HHE 4 cylinder 3 stage air compressor. He said he was very proud of me how quickly I have learned how to rebuild these monster Reciprocating air compressors. Fran Stirpe passed away in the early 1990's but will never be forgotten by me.

I also have to thank Burdette Stier, from Elliott Company, that worked at Commercial Machine Works as a representative for Elliott Company (United Technologies) overseeing all Elliott Pap Centrifugal Compressors, Blowers and the YR Turbine line repairs. In 1981 when I started my career in this field, Burdette Stier worked with me and trained me on this entire Elliott line. I appreciate Burdette Stier's patients and knowledge he gave me the time from 1981-1985. He was a tremendous teacher with an astonishing knowledge of turbines, blowers and centrifugal compressors and the mechanical ability he had within him.

Another one of my mentors was Alfredo Jones who I really have to thank for teaching me work ethics, mechanical ability, field machining skills and designing along with boiler feed pump repairs. He preached to me that I must be meticulous and a perfectionist. Most of all, but not least, to do the best job on anything you work on because you should be proud of your work.

I would also like to thank Zigfried (Ziggy) Schulz as an outstanding all around person and mentor who was a previous employer of mine which also took me under his wing to encourage me and make myself a better all around person in both life and industry. Still to this day Ziggy and I are good friends and keep in touch. I am very proud and thankful to have had all these highly regarded men that influenced me and my work ethics, taught me, trained me and helped build me into the person I am today.

Starting B&G RESCO

In 2001 I decided to start my own company and named it B&G Rotating Equipment Service Company, Inc. "B" for Breseman and the "G" stands for girls as I have three daughters. Still to this day I enjoy being a hands-on Mechanic/Machinist repairing the equipment to the best of my ability and I am very proud of the work I have done when it leaves the shop. I am very meticulous with everything I do in this shop from cleaning, inspecting, repairing, quality control to packaging up every job as I was taught by mentors to be.

The main reason I started my own business was to be able to do the best job I could without a boss pushing me to take short cuts in order to save time and money which would sacrifice quality and workmanship. I am strongly against taking short cuts to save time and money sacrificing quality and workmanship. I take much pride in my work before, during and after the parts leave the shop. I want to make sure my customers are very happy when they receive my parts to the Service Representatives that assembles my parts into the compressor that they are being used in.

I also perform all shop balancing with the latest state of the art Schenck Balance Machines. The reason why I purchased these Balance Machines brand new and perform all my own Rotor Assembly Balancing Operations In-House myself was because I was not satisfied with the level of quality I was receiving outsourcing my balancing jobs. So in 2006 I purchased two brand new Schenck Balance Machines so you can be sure that those rotor assemblies or bullgear's you send in to me or if I manufacture them and sold them as an assembly are balanced correctly. I have in the past and will in the future always balance far beyond the OEM Specifications if possible. I just don't stop when it is good enough so you can be assured that if it is all assembled correctly, all vibration levels will be at their lowest possible that can be obtained ensuring longevity of your compressor if maintained properly. I have received a Certificate of Achievement for completing an Advanced Training Program with IRD Mechanalysis Inc. in 1987. Both of my balance machines are O.E.M. certified on a regular basis.

B&G Rotating Equipment Service Equipment Company, Inc. is very proud of our companies workmanship, services provided, high quality parts that cannot be matched by other competitors and we just love to make our customers happy. It is very rewarding when B&G RESCO's customers receive their parts and service and are completely happy and satisfied, and they call me to let me know, or email me with a thank you for the excellent workmanship I performed, or parts that they received not to mention our parts protection safe packaging practices. I also would like to thank all of my customers for their loyalty, business, support and friendship throughout the years.